Enhancing quality to satisfy the customers” is one of the objectives of our company’s quality focused policy. It is also the major reason why our products are sold all over the world. To ensure quality, all new technologies are first vetted in pilot environments.

Mass production will only initiate if the new process meets our standards and the related standard operating procedures have been fully developed and accepted. Our production quality control system is extended to two opposite ends of the supply chain, from raw material procured to delivered products, and quality satisfaction metrics are rigorously examined.

OUR PRODUCTS

We have following Grades:

Injection / Extrusion Grades

- PBT -Unfilled, Glass Filled grades range from-15%,30%.

- PBT-FR- Grade Unfilled, glass Filled ranges from-15%,30%.

Our materials Properties:

- Excellent electrical property

- Excellent temperature resistance, high heat distortion temperature.

- Excellent mechanic and chemical property

- Excellent weather-ability

- Excellent wear property

- Excellent moldability

- High resistance to fuels, oil, fats and many solvents

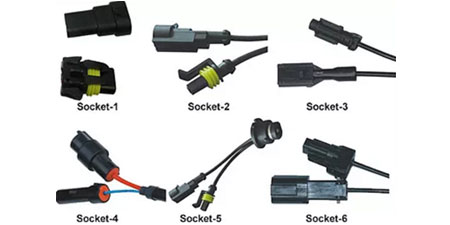

PBT is mostly used for electrical /Electronic manufacturing, Automotive parts, etc…

Chang Chun has a world-class production facility of copper clad laminate board and the production capacity is ranked at the top in the world. Products are supplied to well-known electronic, computer, and circuit printing companies domestically and overseas. The market of the other products cover electronic, electrical engineering, semi-conductor, home appliances, communication, coating, construction, dinnerware, container, and foundry industries.